Daim ntawv thov: dav siv nyob rau hauv brushless lub cev muaj zog, mus tas li hlau nplaum muaj lub cev muaj zog, textile lub cev muaj zog, tsheb tsav, mus tas li hlau nplaum ncaj tsav lub cev muaj zog, linear lub cev muaj zog, cua txias compressor lub cev muaj zog, mechanical khoom ruaj khov hlau nplaum lub cev muaj zog, Marine generator, mus tas li hlau nplaum generator, mus tas li hlau nplaum propulsion lub cev muaj zog , mining mus tas li hlau nplaum lub cev muaj zog, coupling lub cev muaj zog, tshuaj lom neeg hlau nplaum lub cev muaj zog, tsav lub cev muaj zog rau EV, twj tso kua mis, EPS lub cev muaj zog, sensor thiab lwm qhov chaw.

Khoom customized: hlau nplaum yog tag nrho customized, ntev yuav yog los ntawm 0.5mm-200mm, dav los ntawm 0.5mm-150mm, thickness ntawm 0.5mm-70mm, uas yuav ua tau raws li cov neeg muas zaub feem ntau 'yuav tsum tau.

Txheej: NdfeB hlau nplaum yog ib qho yooj yim rau oxidize, yog li feem ntau nws xav tau ib txheej, cov txheej uas siv nyob rau hauv kev ua lag luam xws li:

1. ZN plating (ib hom hlau txheej, tshuaj tsuag ntsev tuaj yeem ncav cuag 24-48 teev, kev ua haujlwm siab, yog li nws yog ib qho kev xaiv zoo tshaj plaws rau cov neeg siv khoom feem ntau).

2. NICUNI (ib hom hlau txheej, tshuaj tsuag ntsev tuaj yeem ncav cuag 48-72 teev, tus nqi ua haujlwm siab dua ZN, tab sis tseem siv dav hauv kev ua lag luam, kev sib dhos yog hnyav, cov khoom siv tiv thaiv corrosion ntawm cov neeg siv khoom tuaj yeem. xaiv).

3. Epoxy (non-metallic txheej, uas tsis yog-magnetic conductivity, yuav txo tau lub cev muaj zog eddy tam sim no poob, ntsev tshuaj tsuag mus txog 72-96 teev, tus nqi siab tshaj ZN ib NICUNI txheej.)

4. Lwm cov txheej uas tseem siv tau: Phosphate, Sn, Au, Ag, Parylene thiab lwm yam ...

Kev kam rau siab: Feem ntau peb cov hlau nplaum kam rau ua yog +/- 0.05mm tom qab txheej.

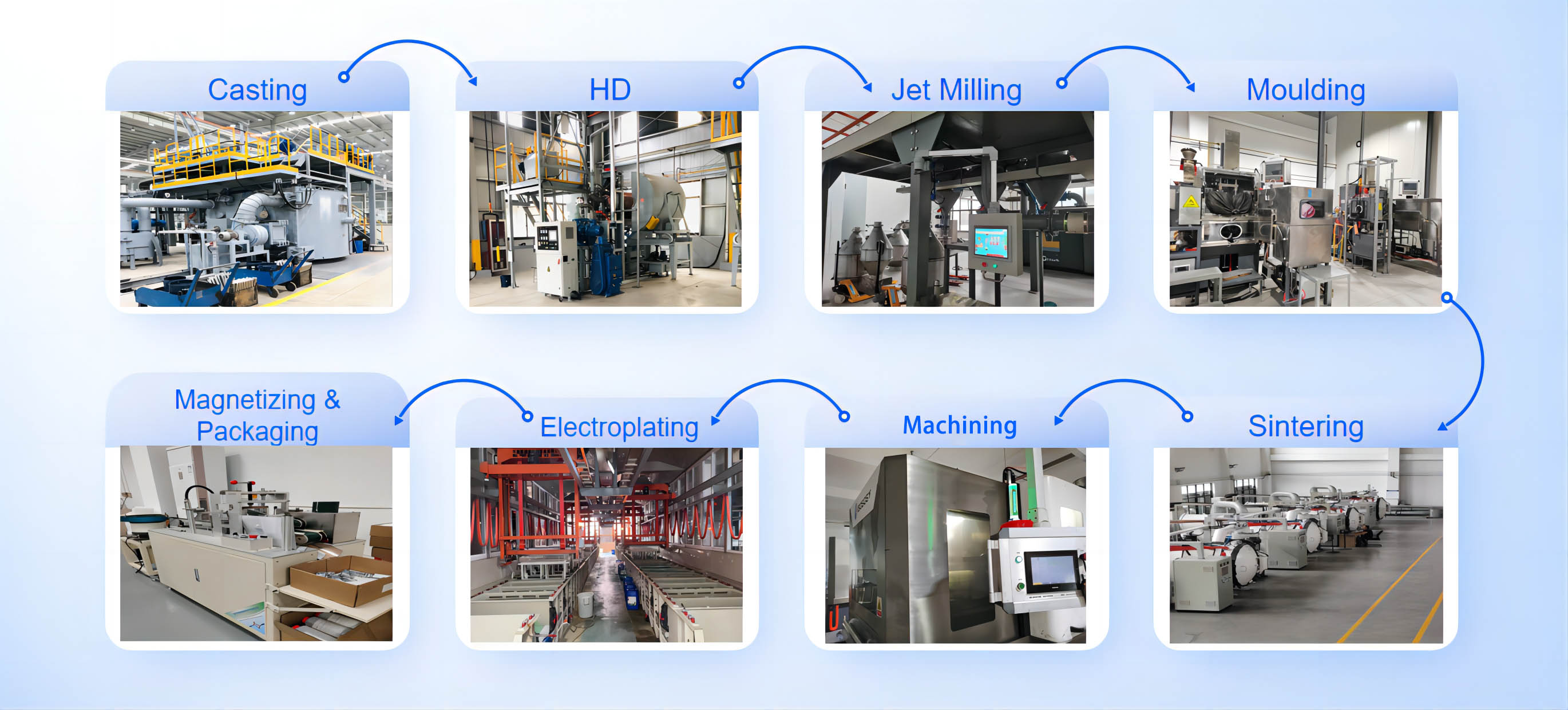

NdFeB Production Process

Txheej Taw Qhia

| Nto | Txheej | Thickness μm | Xim | SST Sijhawm | PCT Sijhawm | |

| Nickel | Ni | 10 ~ 20 | Bright Silver | > 24-72 | > 24-72 | |

| Ni+Cu+Ni | ||||||

| Dub Nickel | Ni+Cu+Ni | 10 ~ 20 | Xim dub | > 48-96 | > 48 | |

| Cr3 + Zinc | Zn C-Zn | 5 x8 | Brighe Blue Xim Xim | > 16-48 > 36-72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Nyiaj | > 36-72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10 ~ 15 | Kub | > 12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Nyiaj | > 12 | > 48 | |

| Epoxy | Epoxy | 10 ~ 20 | Dub / Grey | > 48 | --- | |

| Ni + Cu + Epoxy | 15-30 Nws | > 72–108 | --- | |||

| Zn + Epoxy | 15 ~ 25 | > 72–108 | --- | |||

| Passivation | --- | 1 ~3 | Tsaus Grey | Kev tiv thaiv ib ntus | --- | |

| Phosphate | --- | 1 ~3 | Tsaus Grey | Kev tiv thaiv ib ntus) | --- | |

Cov yam ntxwv ntawm lub cev

| Yam khoom | Tsis muaj | Siv tus nqi | Chav tsev |

| Sib Nqus Sib Nqus Cov khoom | Reversible Temperature Coefficient Ntawm Br | -0.08 - 0.12 | % / ℃ |

| Reversible Temperature Coefficient Ntawm Hcj | -0.42~-0.70 | % / ℃ | |

| Tshwj xeeb kub | 0.502 ib | KJ·(Kg· ℃)-1 | |

| Curie Kub | 310-380 : kuv | ℃ | |

| Mechanical Physical Cov khoom | Qhov ntom | 7.5-7.80 Nws | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Hluav taws xob Resistance | 1.4x10-6 | μQ os | |

| Compressive zog | 1050 | MPa | |

| Tensile zog | 80 | Mpa | |

| Khoov zog | 290 | Mpa | |

| Thermal conductivity | 6.8.95 ib | W/m · K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion (C⊥) | -1.5 | 10-6 ℃ -1 | |

| Thermal Expansion (CII) | 6.5 | 10-6 ℃ -1 |

Daim duab Display