Nws yog haum rau ntau lub teb thiab kev lag luam, xws li electronics, kev kho mob, tsheb, machinery, thiab lwm yam. Txawm hais tias nyob rau hauv sensors, motors, suab khoom los yog lwm yam kev siv, peb cov khoom ib txwm qhia tau zoo heev kev ua tau zoo thiab zoo ib yam.Peb lwm cov duab NdFeb cov khoom lag luam twb tau ua tiav zoo hauv ntau txoj haujlwm thiab kev siv.

Piv txwv li, nyob rau hauv kev tsav tsheb ntawm lub tsheb hluav taws xob, peb cov khoom muaj txiaj ntsig zoo rau lub cev muaj zog thiab cov khoom siv hluav taws xob.Peb kuj muab kev txhawb nqa tseem ceeb sib nqus rau ntau yam khoom siv kho mob hauv cov khoom siv kho mob.Yog li cov neeg siv khoom tau qhuas qhov zoo thiab kev ua haujlwm ntawm peb cov khoom.

Hauv kev sib tw ua lag luam, peb cov khoom muaj txiaj ntsig zoo dua.Vim tias peb muaj cov txheej txheem tsim khoom thiab cov khoom siv los ua kom muaj kev ruaj ntseg thiab sib xws ntawm cov khoom zoo.Peb tseem niaj hnub tsim thiab tsim kho tshiab kom tau raws li qhov hloov pauv ntawm peb cov neeg siv khoom.Peb cov txheej txheem nruj me ntsis tswj txhua qhov txuas kom ntseeg tau tias cov khoom ua tau raws li qhov xav tau zoo.

Peb muab ntau yam kev daws teeb meem kom tau raws li cov kev xav tau tshwj xeeb ntawm peb cov neeg siv khoom.Peb pab neeg tshaj lij ua haujlwm nrog peb cov neeg siv khoom kom nkag siab txog lawv cov ntawv thov thiab cov kev xav tau txhawm rau muab cov kev daws teeb meem rau lawv ntawm kev xaiv cov khoom zoo tshaj plaws thiab tsim qauv.

Peb tau cog lus los muab peb cov neeg siv khoom nrog cov kev daws teeb meem los xyuas kom meej tias lawv tuaj yeem ua tiav cov txiaj ntsig ntawm lwm cov duab Ndfeb cov khoom kom ua tiav kev ua tau zoo thiab kev ua tau zoo.

Peb kuj muab kev pabcuam zoo tom qab muag rau peb cov neeg siv khoom.Seb nws yog lub installation, commissioning los yog txij nkawm ntawm cov khoom, peb yuav muab kev pab raws sij hawm thiab kev taw qhia.

Peb ua raws li lub hauv paus ntsiab lus ntawm cov neeg siv khoom ua ntej, ib txwm muab cov neeg siv khoom txaus siab rau thawj qhov chaw, thiab siv zog los muab cov neeg siv khoom zoo tshaj plaws tom qab kev muag khoom.

Raws li cov chaw tsim khoom ntawm Ndfeb, peb lwm cov duab NdFeb cov khoom lag luam sawv tawm rau lawv cov khoom sib nqus muaj zog, cov qauv tsim tshwj xeeb thiab ntau yam kev siv.

Peb cov kev txhawb nqa, kev tshuaj xyuas cov neeg siv khoom, kev pab cuam tom qab muag thiab kev sib tw kom zoo ntxiv ntxiv dag zog rau peb txoj haujlwm hauv kev ua lag luam.Peb yuav txuas ntxiv cog lus rau kev tsim kho thev naus laus zis thiab cov khoom lag luam optimization, muab cov neeg siv khoom zoo dua thiab muaj ntau yam duab NdFeb cov khoom los ua kom muaj txiaj ntsig zoo rau kev txhim kho thiab kev tsim kho tshiab ntawm txhua qhov chaw ntawm lub neej.

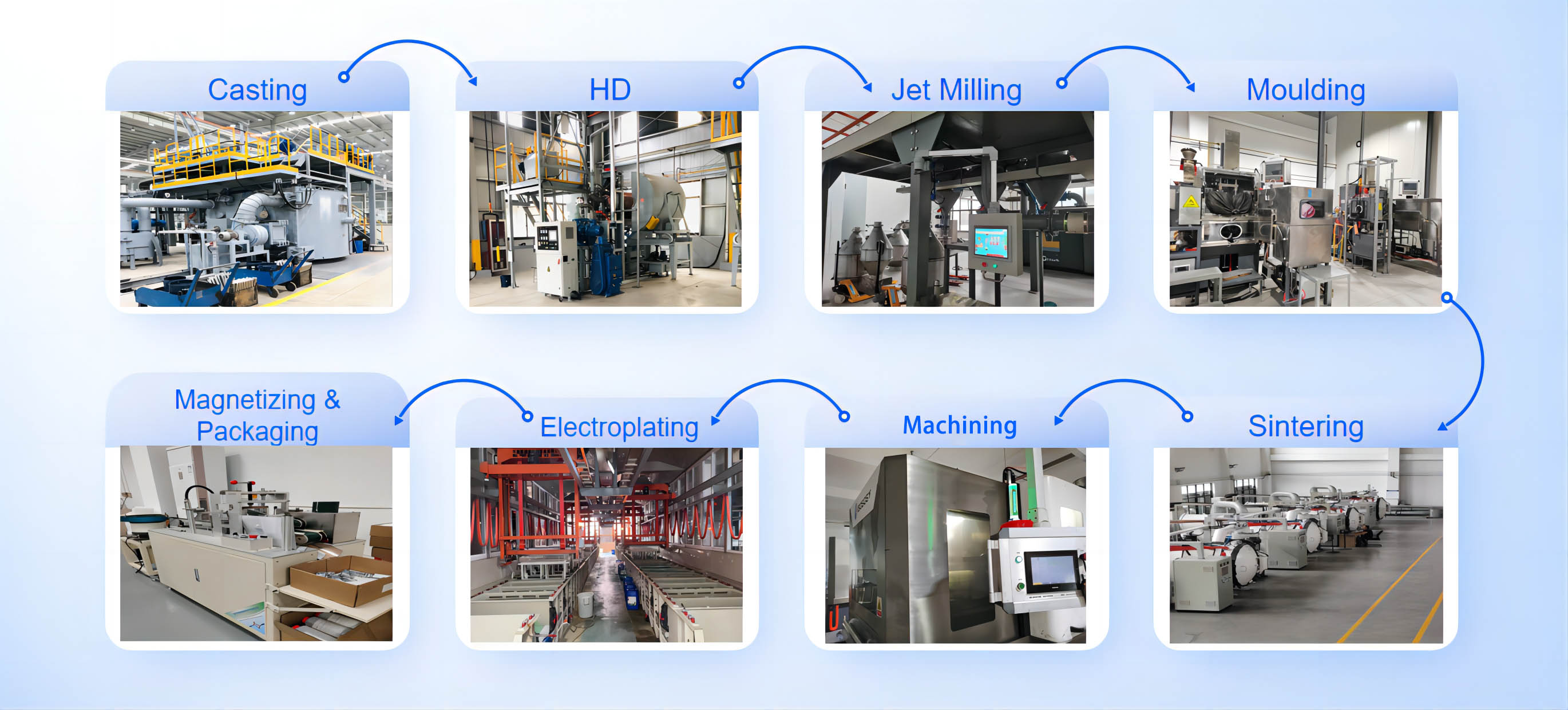

NdFeB Production Process

Txheej Taw Qhia

| Nto | Txheej | Thickness μm | Xim | SST Sijhawm | PCT Sijhawm | |

| Nickel | Ni | 10 ~ 20 | Bright Silver | > 24-72 | > 24-72 | |

| Ni+Cu+Ni | ||||||

| Dub Nickel | Ni+Cu+Ni | 10 ~ 20 | Xim dub | > 48-96 | > 48 | |

| Cr3 + Zinc | Zn C-Zn | 5 x8 | Brighe Blue Xim Xim | > 16-48 > 36-72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Nyiaj | > 36-72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10 ~ 15 | Kub | > 12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Nyiaj | > 12 | > 48 | |

| Epoxy | Epoxy | 10 ~ 20 | Dub / Grey | > 48 | --- | |

| Ni + Cu + Epoxy | 15-30 Nws | > 72–108 | --- | |||

| Zn + Epoxy | 15 ~ 25 | > 72–108 | --- | |||

| Passivation | --- | 1 ~3 | Tsaus Grey | Kev tiv thaiv ib ntus | --- | |

| Phosphate | --- | 1 ~3 | Tsaus Grey | Kev tiv thaiv ib ntus) | --- | |

Cov yam ntxwv ntawm lub cev

| Yam khoom | Tsis muaj | Siv tus nqi | Chav tsev |

| Sib Nqus Sib Nqus Cov khoom | Reversible Temperature Coefficient Ntawm Br | -0.08 - 0.12 | % / ℃ |

| Reversible Temperature Coefficient Ntawm Hcj | -0.42~-0.70 | % / ℃ | |

| Tshwj xeeb kub | 0.502 ib | KJ·(Kg· ℃)-1 | |

| Curie Kub | 310-380 : kuv | ℃ | |

| Mechanical Physical Cov khoom | Qhov ntom | 7.5-7.80 Nws | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Hluav taws xob Resistance | 1.4x10-6 | μQ os | |

| Compressive zog | 1050 | MPa | |

| Tensile zog | 80 | Mpa | |

| Khoov zog | 290 | Mpa | |

| Thermal conductivity | 6.8.95 ib | W/m · K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion (C⊥) | -1.5 | 10-6 ℃ -1 | |

| Thermal Expansion (CII) | 6.5 | 10-6 ℃ -1 |

Daim duab Display